| Where is CD-RW media heading? |

The Internet has brought the world together in a way never before seen. Massive amounts of information are available at our fingertips. In essence, the world has gotten a lot smaller because of the lightning speeds that this information is available. But the Internet by itself is transient. Once information is found in this vast "library", it needs to be captured… and at least temporarily stored. Optical storage media (CD-R, CD-RW, DVD-rew) embraces this need perfectly.

DVD-rew technology will ultimately rule the optical storage media arena. But DVD-rew as a viable storage method for the mass market is at least a few years in the future. For now, CD-R/RW technology is the most viable near term solution; with much higher storage capacity over floppies (650 Mbytes vs. 1.44Mbytes) and much lower cost over other types of high capacity removable storage media ($5/Gbyte vs. $100/Gbyte).

The CD-R/RW drive market is expected to grow rapidly starting in the year 2000. Floppy drives will begin to disappear in the year 2001 and CD-R/RW drives will take their place. Manufacturers have accepted the CD-R/RW format and are moving to integrate these drives as a standard component in most PCs. This was very evident at COMDEX last November. The annualized run-rate of CD-RW drives is 30 million units at the beginning of year 2000, more than doubling the capacity of 1999. Production capacity is the only limiting factor in the growth of CD-R/RW drives for the next 3 years.

While the CD-R/RW drive market enjoys enormous success and growth in the near future, what lies ahead for the CD-R/RW media market is still unclear. What happened to the promise of replacing CD-R with editing ability and affordable pricing?

1999 was a disappointing year for CD-RW disc media. The reasons are many. The most obvious was the lack of backward compatibility to the large installed base of CD players. Secondly, CD-RW was not as easy to use as CD-R. There was still confusion regarding compatibility across different drive speeds and number of read heads. The third reason was the price. However, as 1) multi-read installed base grows, 2) software and product become more mature (and it is getting there), 3) price comes down, CD-RW media growth will take off towards the second half of year 2000.

Why the subtle, yet significant shift from CD-R discs to CD-RW discs? The reasons are not readily obvious because of the short product history of CD-R discs. One of the reasons is the comfort level of consumers. CD-R discs can be written only once. Most people feel much more comfortable knowing they have more than one try at recording and storing data. On a CD-R disc, once a mistake is made the disc is scraped and must be thrown away. This is not the case with CD-RW discs. CD-RW discs can be re-written, making it much more forgiving to the end user. In addition, the knowledge that the CD-RW discs can be re-used and therefore inherently more cost effective is appealing incentive.

But below these superficial reasons, another more technical reason for the shift is a critical fundamental quality problem with CD-R discs that CD-RW discs do not have. The dye material used in CD-R discs is first, an organic material and second, deposited using a "spin-on" process. The adhesion of a spin-on process is inherently poor. The dye layer delaminates (separates) under thermal expansion (e.g. stored inside a car) or mishandling (e.g. dropped disc) rendering the disc useless. The dye (organic material) is also sensitive to light (UV). Because data is stored in the dye layer, damage due to UV exposure again renders the disc useless. Also, the dye layer is constantly going through aging (hardening) and becomes brittle and fragile over time. The laws of physics do not change. Little can be done to solve the CD-R quality problem.

The CD-R delamination problem is not a theory. This is evident by PC users and music lovers everywhere --- when a CD-R disc is mishandled, subjected to heat, or even just used intensively, the saved data is lost and the disc must be thrown away. That coupled with the fact that CD-R gives the end user one chance at storing data and is not re-usable could prove to be fatal shortcomings for this media.

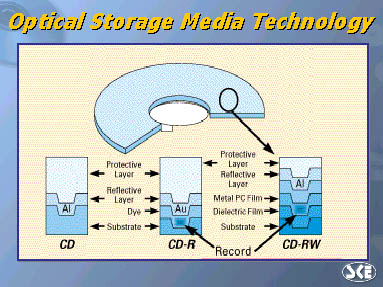

Fig. 1. Optical Storage Media Technology

Fig. 1 above shows the technology trend in optical storage media, increasing in technology complexity from left (CD) to the right (CD-RW).

On the left is shown the cross-section of a CD disc (audio or ROM). The digital information is "stamped" onto the plastic substrate. A single aluminum layer reflects the digital information to the reader. The reflective layer is deposited by a technique called "sputtering", a process also known as physical vapor deposition (PVD).

In the center is shown the cross section of a CD-R disc (recordable). An organic dye is dispensed onto the disc using a spin-on process. During the recording of data on CD-R disc, a laser "burns" the digital information onto the dye layer. Once data is burned into the dye it cannot be "re-burned". This is why CD-R discs are good for recording once only. A single gold or silver layer, deposited by sputtering, is used to reflect the laser beam back to the reader.

On the right is shown the cross section of a CD-RW disc (rewritable). There are four layers of films, all deposited by sputtering. Information is "written" in a material that is capable of going through "phase change". This phase changes lead to changes of the material properties, making it either reflective or non-reflective depending on the cooling rate. So, by bringing the phase change material to near melting temperature and controlling the cooling rate with the optical laser, the information is "written". By heating up the material again and converting it from amorphous to crystaline, the information is "erased". In terms of complexity of technology, this is a quantum leap from its predecessor, the CD-R disc. The film properties of each layer of a CD-RW disc must be controlled to very tight specifications during the manufacturing process. The film quality is critically determined by the design of the "cathode" used during the sputtering process.

All the layers of material on a CD-RW disc are inorganic and are deposited using sputtering. The layers are "diffused together" under glow-discharge energy, called a plasma. During sputtering, the molecules that eventually make up the deposited layers are accelerated to a high speed and impinged into the substrate or previously deposited layer. The result is extremely good bonding between the layers of different materials all the way to the plastic substrate on a CD-RW disc. This good bonding eliminates the layer delaminating problem on CD-RW discs. Also, the use of inorganic materials eliminates the problems of UV light sensitivity and aging seen on the CD-R dye layer.

The materials and process used to produce CD-RW discs make it much more robust than CD-R discs. CD-RW discs retain information reliably and are much less susceptible to damage due to heat, UV exposure or rough handling. The ability to retain information without risking damage and data loss gives CD-RW a distinct advantage over CD-R. In addition, the re-usable nature of CD-RW discs appeals to the comfort levels of end-users.

One final key factor that plays a big role in the lacking demand of CD-RW --- price. The cost of producing a CD-RW disc is still much higher than CD-R disc. There are many factors that contribute in the cost of producing discs, ranging from the initial cost of the equipment itself to the overall product yield from the equipment. The role of the equipment manufacturers is very well defined ---the company that comes up with a highly efficient, low cost sputtering machine that narrows the gap between CD-R and CD-RW disc manufacturing costs will win the market.

Part II of this article will compare various techniques used by equipment for sputtering the various layers of material for CD-RW discs. Issues such as how overall media costs are affected by initial equipment and consumable costs, equipment reliability, throughput, and overall product will be explored. Part II will also look at CD-RW vs. DVD-rew disc media production and how the benefits achieved for CD-RW could clearly benefit DVD-rew.

Conclusion:

Until the ultimate rise of DVD-rew discs for optical storage, CD-R/RW discs will fill the need for removable high capacity storage. Demand for CD-RW discs will surge in the years 2000 through 2003 reflecting a shift from CD-R to CD-RW discs. CD-RW discs have clear advantages over CD-R discs in terms of robustness and consumer appeal. At the same time, CD-R discs currently have a clear advantage in lower manufacturing costs.

In order to become the media of choice for those specific applications where CD-RW has clear advantages over CD-R, improvements in the equipment used to make the CD-RW discs are needed. Those improvements are needed primarily in the sputtering equipment area. Lower capital costs, higher yields, lower cost of consumables, better reliability, shorter and less maintenance are all part of these equipment improvements. The benefits of achieving these goals could continue past CD-RW production. It is anticipated that CD-RW production lines can be expanded to DVD-rew production therefore leveraging capital and setup costs.

For new investments during this coming this year, you owe it to yourself to take a closer look at where to put your investment money to best leverage long term growth and profit.

Author: Ken Lee, President and founder of SKE Technology.

Ken spent the last 25 years in Semiconductor R&D front-end equipment. Before SKE, he held senior positions at Applied Materials and Varian Thin Film Division.

[ company information ] [ product information ] [ what's new ] [ careers ] [ site history ] [ contact us ]